Laser Cutter Builds!

This post is going to be a long one. Right now lets just get all the laser pictures up.

Ive built a lot of lasers

I hadn’t really thought about how many lasers I have built, fixed, designed or retrofit in the last few years, but not that I have to quantify it, it’s a lot. Lasers are one of the few CNC tools that just about anyone can walk up to with a piece of art, or an idea and walk away with their widget in just a few minutes with little to no knowledge. That level of accessibility constantly excites me and its just getting easier.

The First Lasers

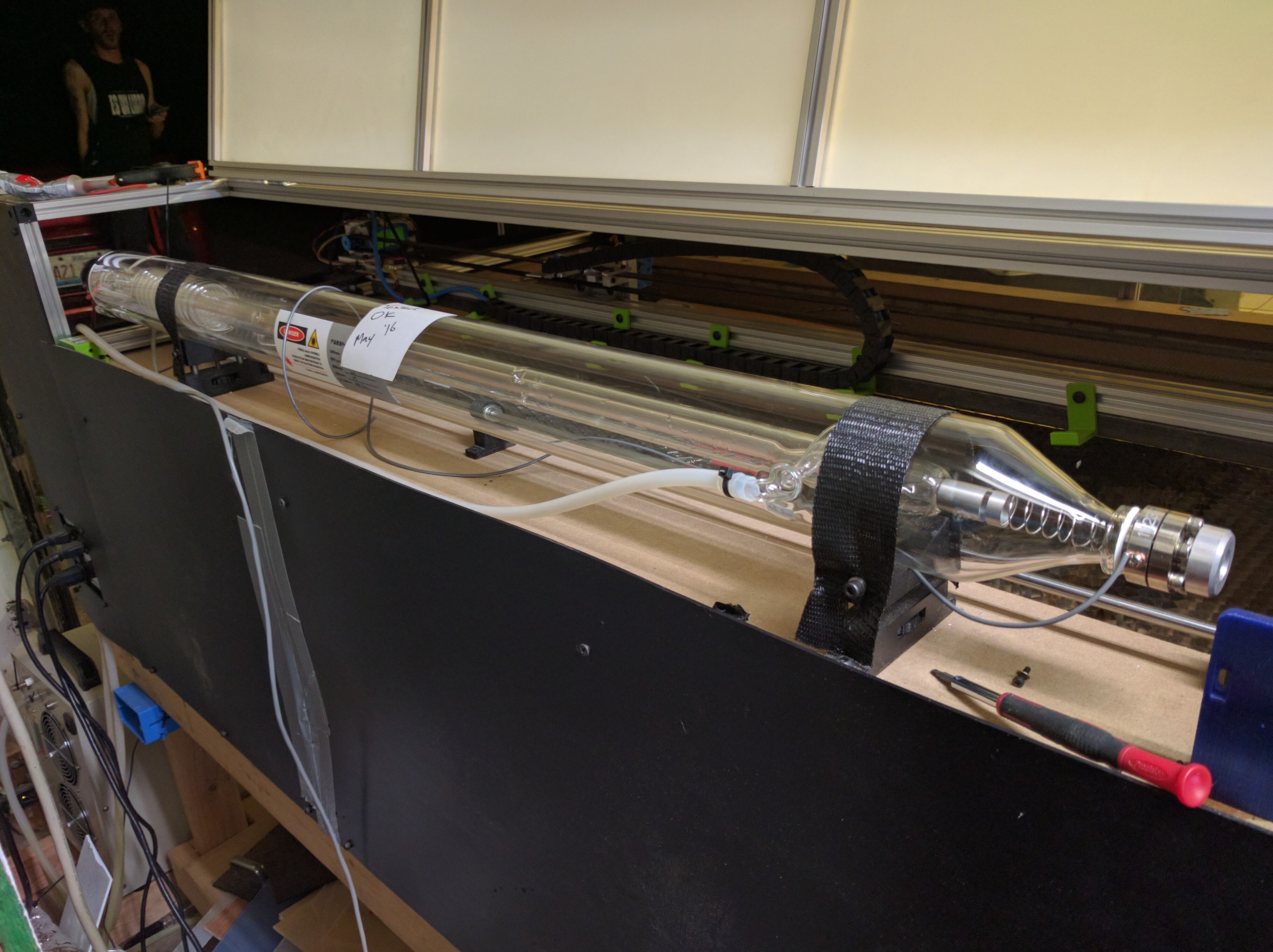

My first laser like a lot of DIY people was a K40. I bought it when the only retrofit controller that was really available was a Chinese DSP option like the AWC608 controller so I spent almost as much as I did on the laser on a control upgrade. It worked well until I blew the tube not running coolant and I decided at that point that I was hooked and if I was gonna buy a new tube it may as well be a big one.

k40 place holder

PowerBlinder5k - First gen

Did you know lasers wont bend to follow issues with your mechanical system? Yea, I did too, but everything is straight in CAD.

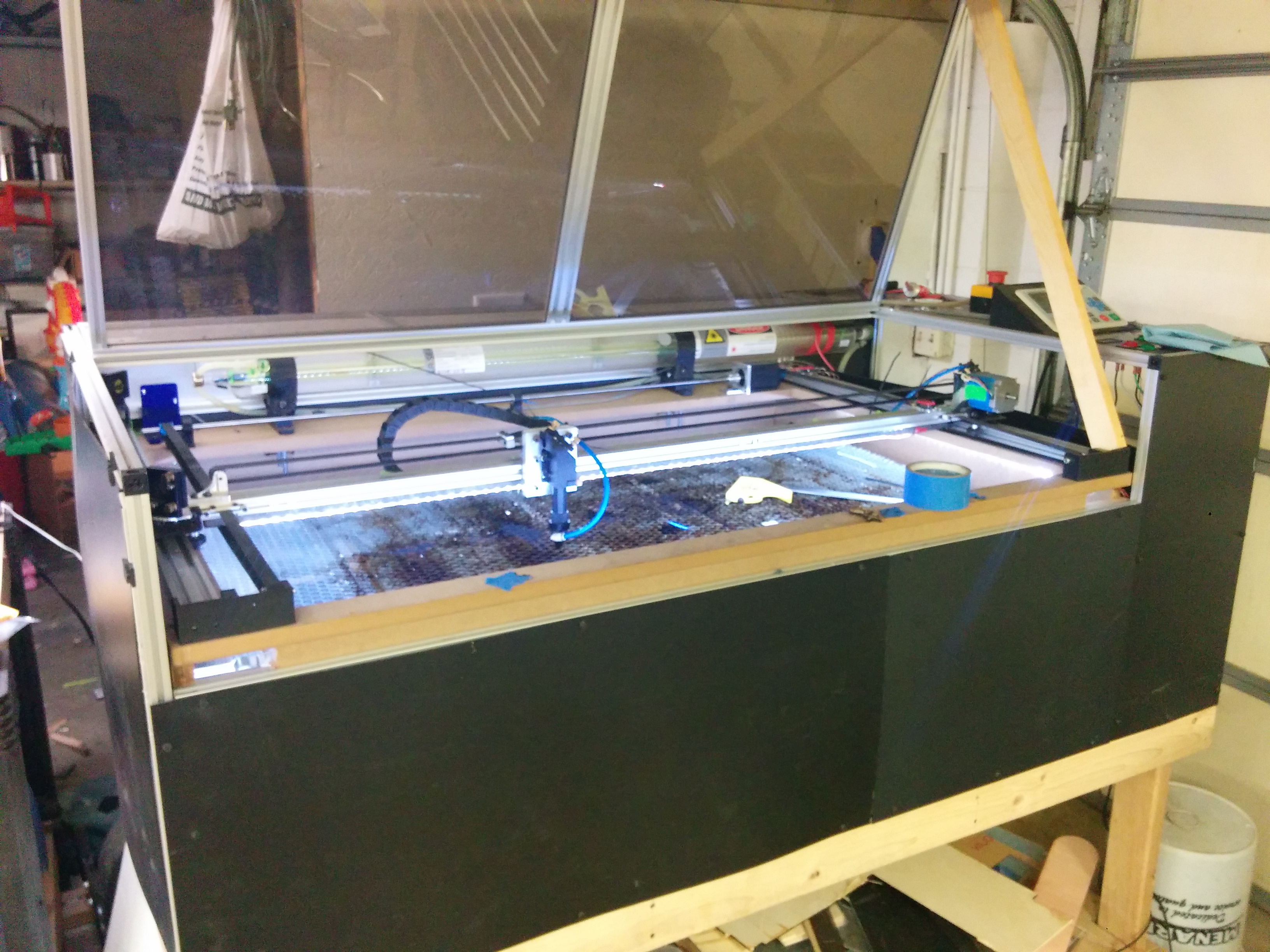

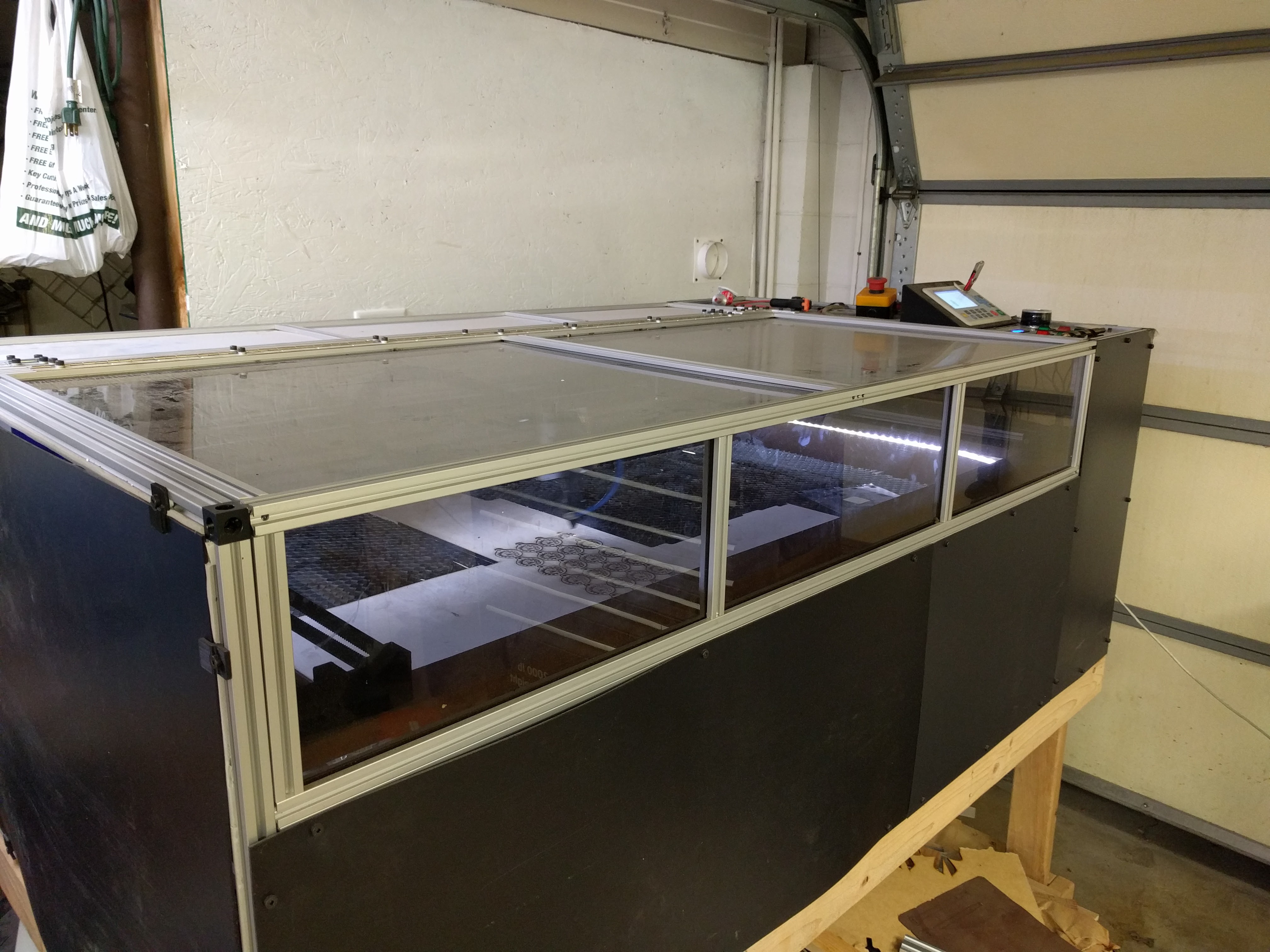

PowerBlinder5k - Second gen

In order to mitigate mechanical misalignment I decided to build everything onto a single motion platform. This made alignment easier as it was all based off of one plane. As long as that plane was not warped I had a good refence to do my alignment from.

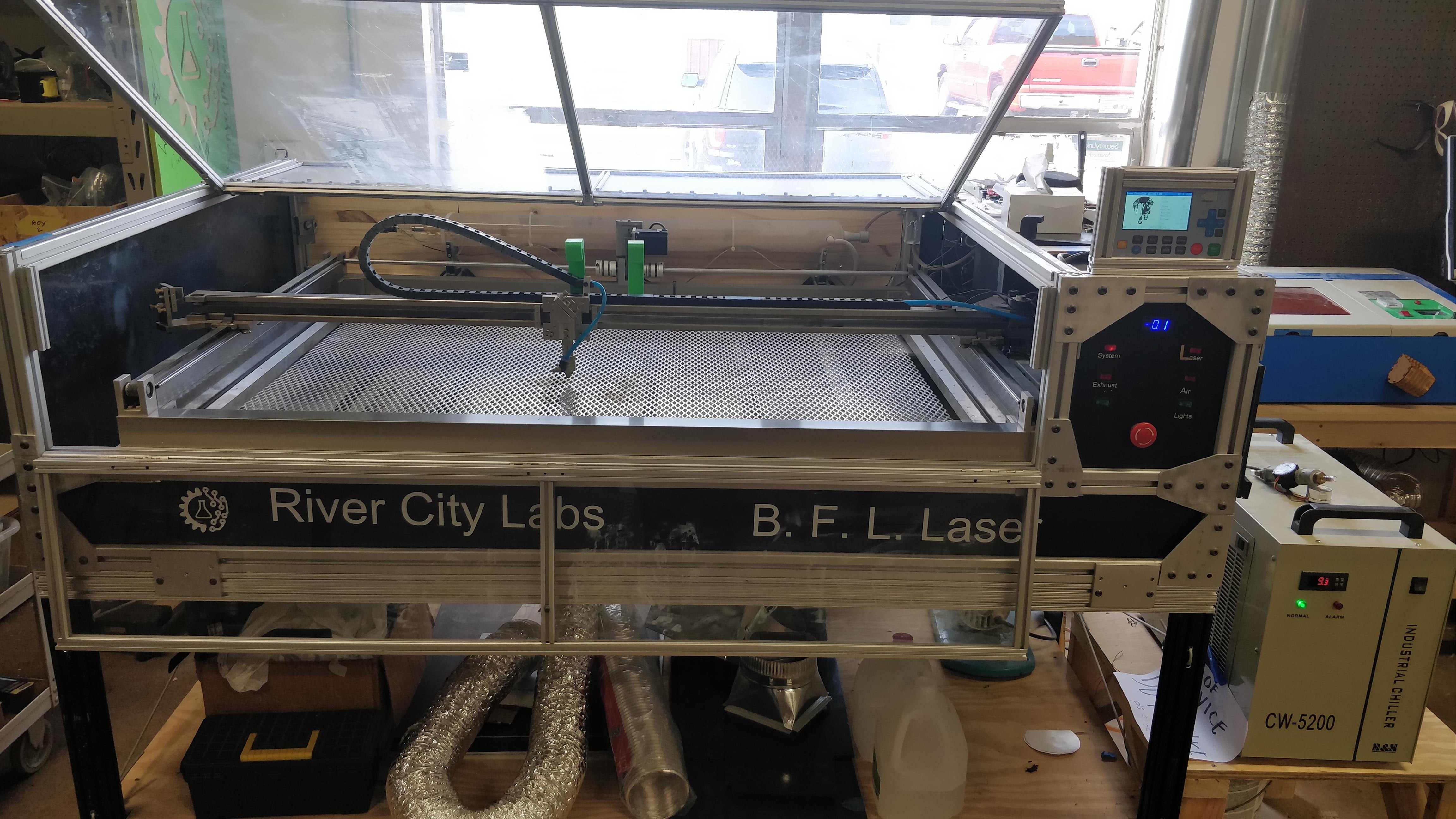

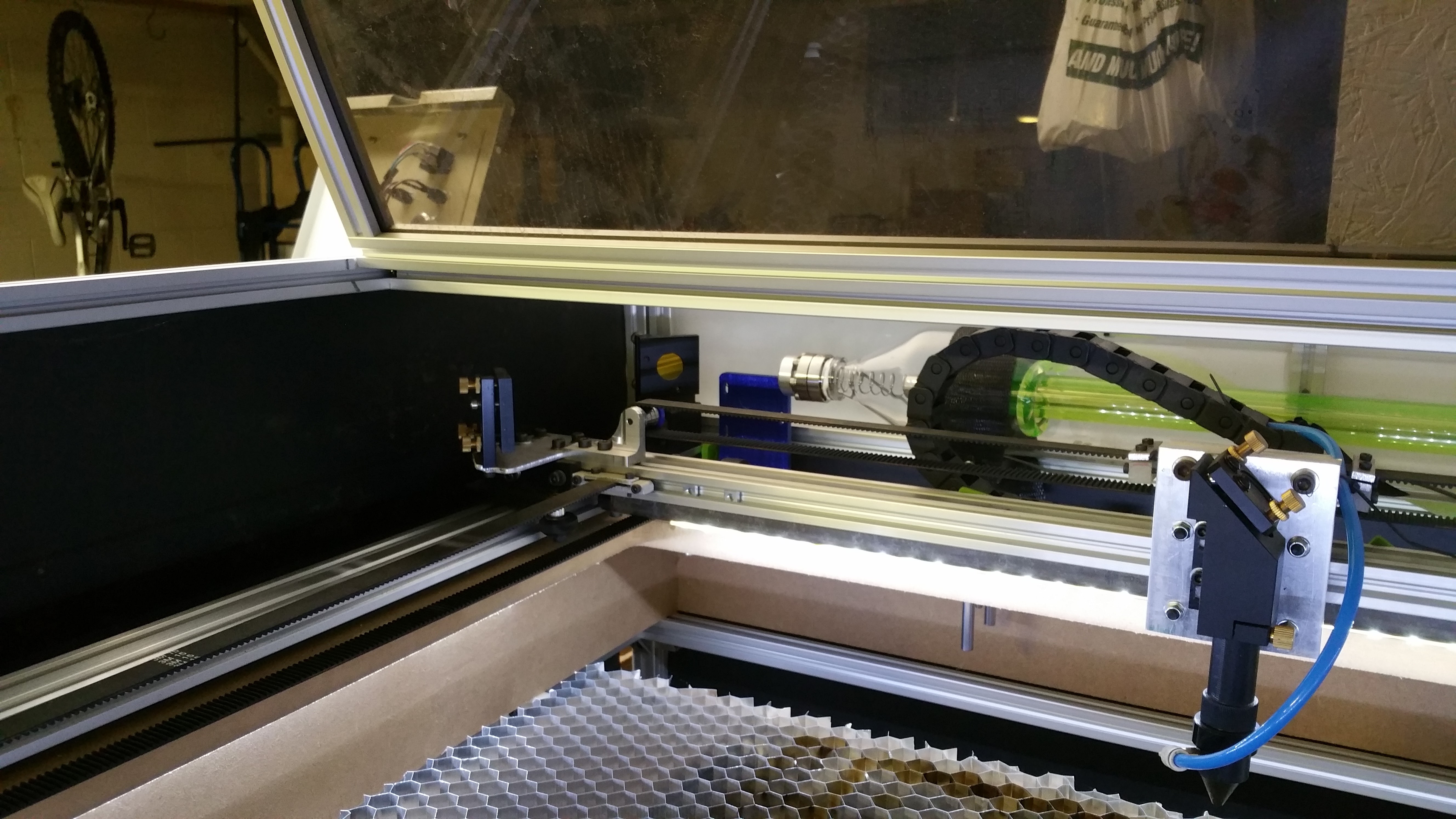

BFL