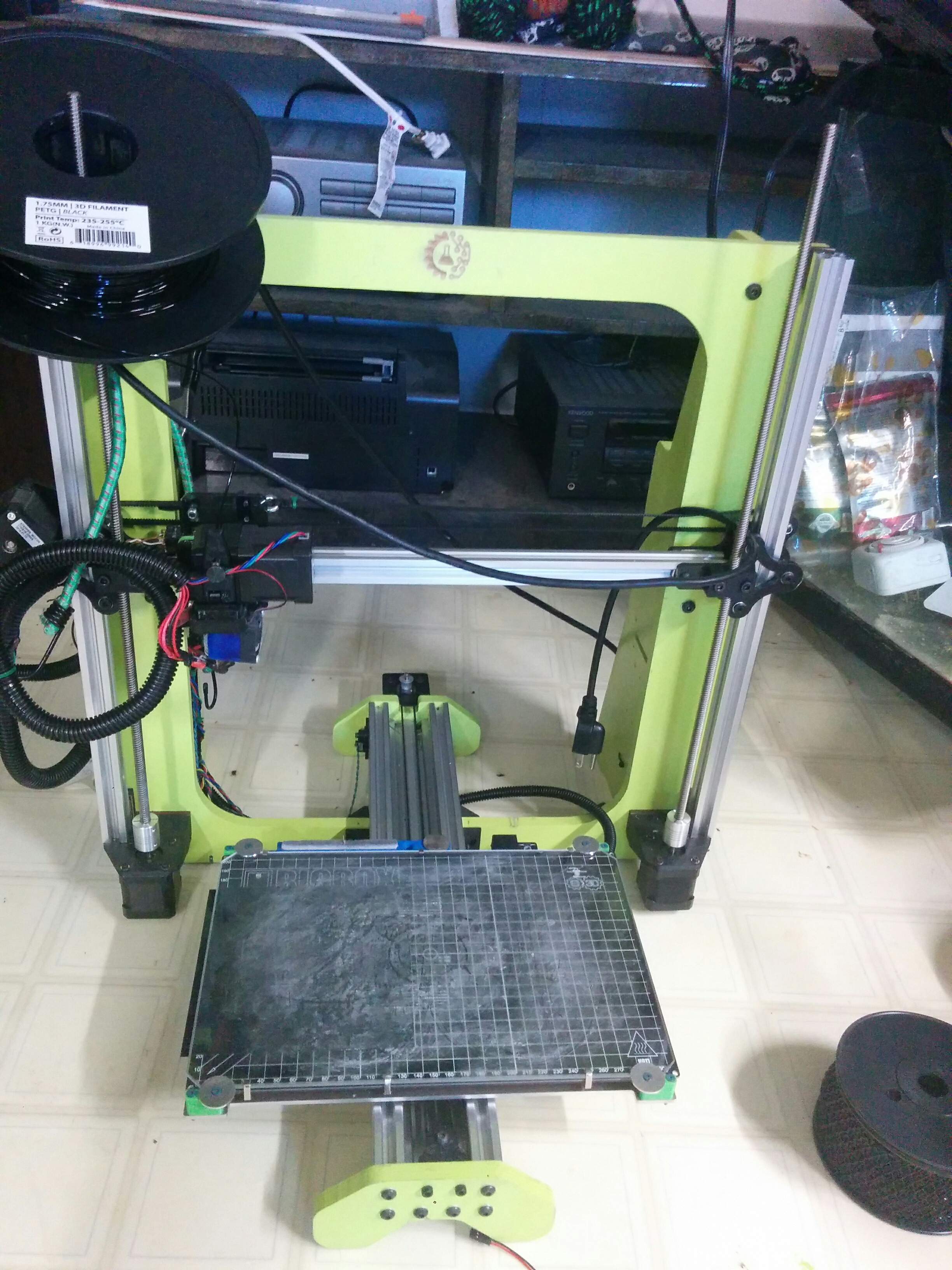

RCL i4 3D printer

RCL i4 Origin

The goal of the i4 project was to build a low part count, easy to build machine that a class could be taught around, and that as many components could be made in a local makerspace as possible. This was also my first fully committed Fusion360 project. I learned a ton doing the full assembly and CAM in fusion over the couple months I spent designing this machine.

The build uses the following:

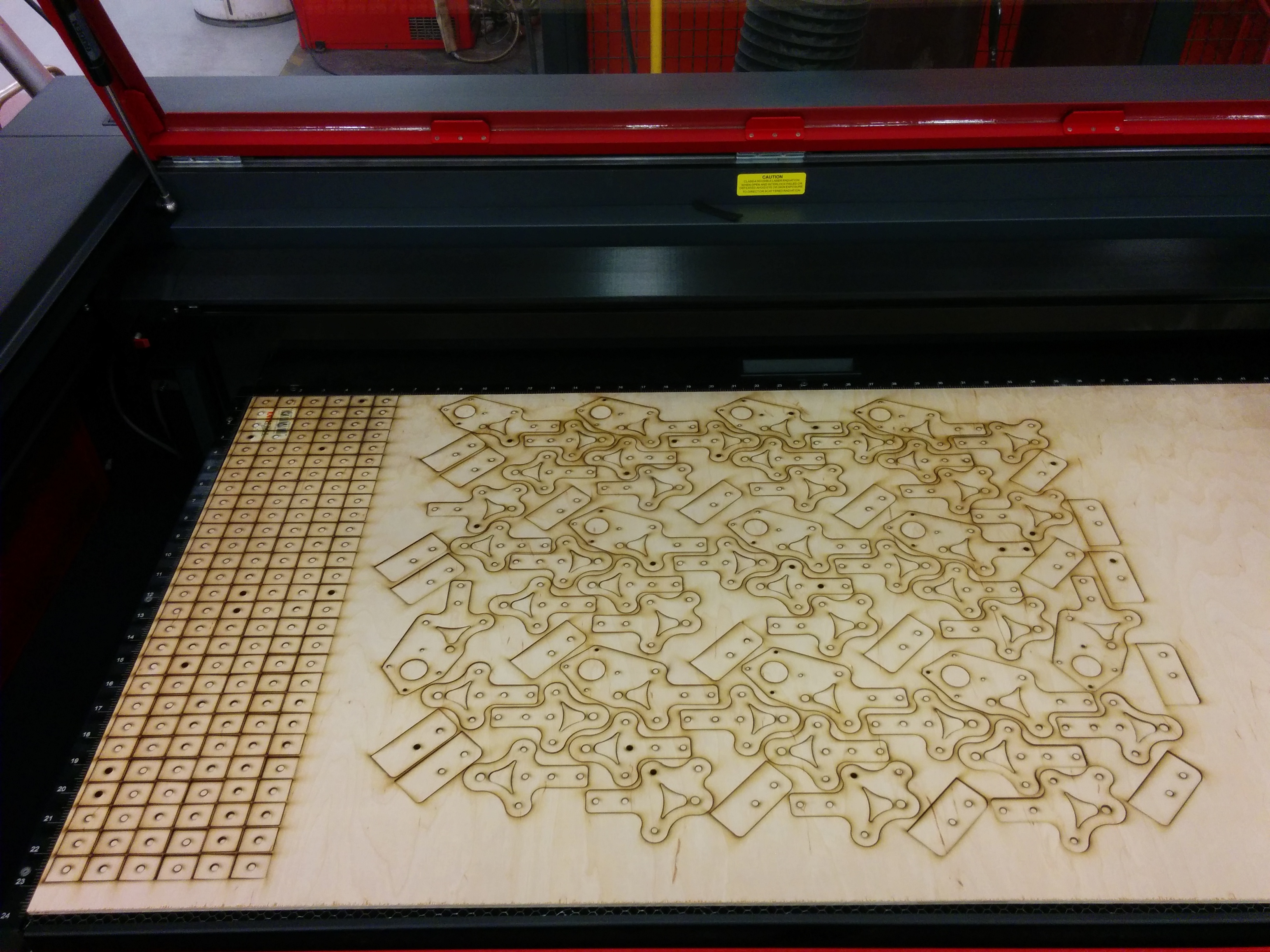

- Frame is 1/2” Baltic Birch plywood to keep cost and weight down All parts from a 2x4’ Sheet

- All printed parts can fit on single build plate

- All brackets are laser cut from 1/4” Baltic Birch, but can be cut from aluminum or printed as well

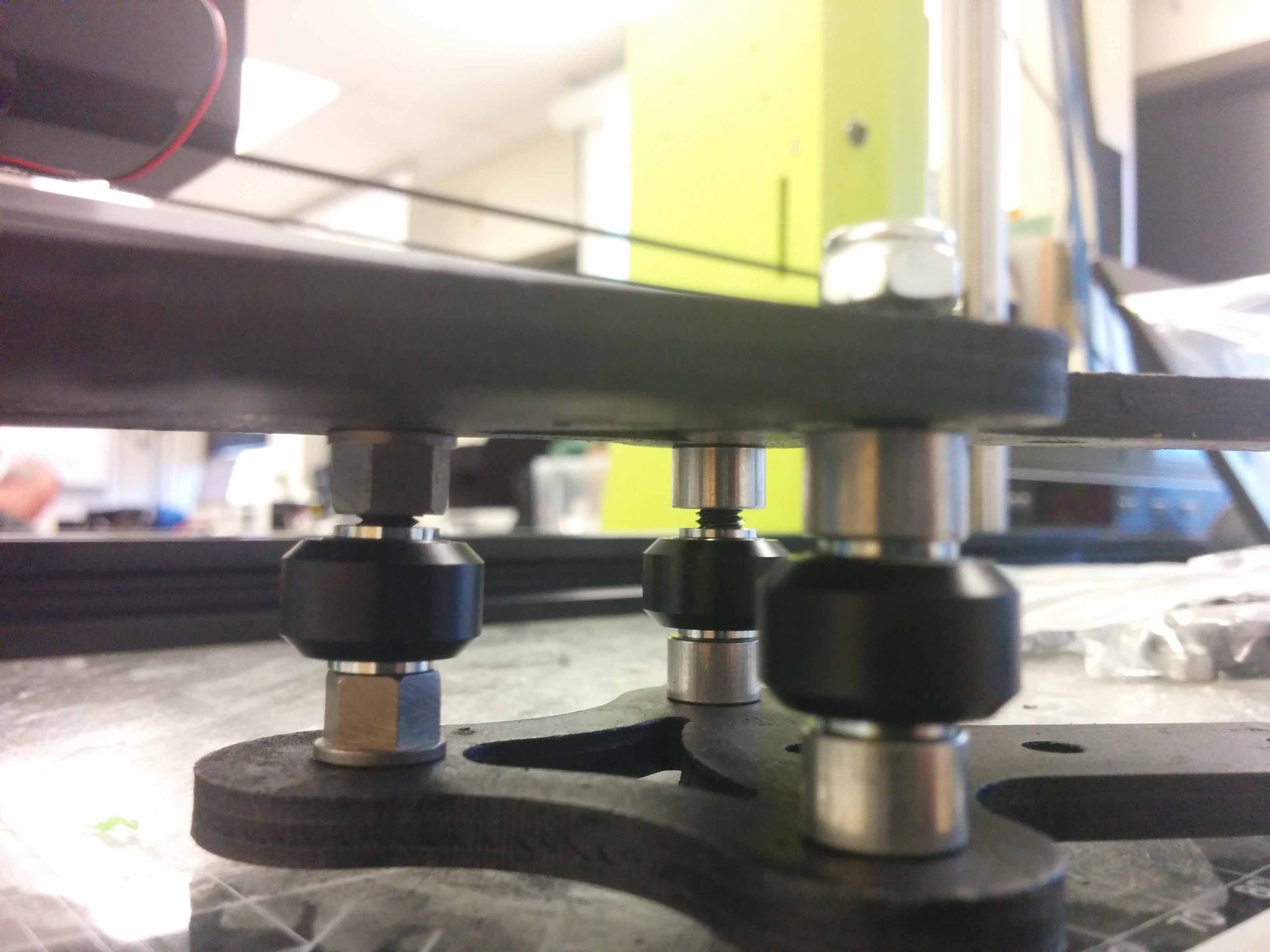

- The build is v-slot based to be as simple to assemble as possible

We arranged a build class on 10 of these printers over 3 build sessions.

All of the source and exisiting documentation can be found on my github at: RCL i4 Github